How do you know that you are using the right forecasting methodology? At which level of your product hierarchy should you forecast? Which products should you focus most of your attention on?

These are the questions that Forecastability Analysis can answer. Forecastability Analysis is a process that evaluates your business’ demand planning challenges and helps your staff focus on steps to address demand variability. The process segments products in multiple unique ways so you can create and apply specific supply chain policies for inventory management and production. It also can evaluate the profitability of your products and product segments. The result is a defined set of rules that you can apply to your business that can make dramatic bottom line improvements.

Why Do You Want to Do it?

The goal of Forecastability Analysis is to improve the accuracy and efficiency of your demand planning. You may be experiencing one or more symptoms that point to a need for a Forecastability Analysis. These include:

- Poor forecast accuracy or accuracy is not improving

- Lengthy and cumbersome forecasting process

- Inventory levels too high

- Frequent Stockouts and/or expedites

There are also other strategic reasons to conduct a Forecastability Analysis. A recent acquisition or divestiture could prompt a need to shift your forecast focus. Something that may be related to the former, a change in staff that requires new-hire training in the forecasting process. Or, a competitor or market shift that changes the landscape for your existing products could reveal an opportunity for improvement.

How Does it Work?

There are 3 essential steps to a good Forecastability Analysis.

Step 1: Analyze Demand History

This step looks at your actual sales history for each product and begins to segment your products by relative value. It also reveals which factors drive demand in your business.

Step 2: Select Forecast Strategy

Here we evaluate multiple forecasting approaches to determine which offers the best accuracy. This includes looking at statistical and non-statistical methods, different product hierarchies, product lifecycle curves, and event / promotion modeling.

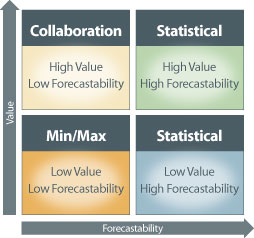

Step 3: Quadrant Analysis

This step gets to the actionable results of Forecastability Analysis. Here, products are segmented and grouped according to how well they forecast and their relative value to the business. The result is a set of specific policies that can be applied to these products that drive the forecast, inventory and capacity planning.

This step gets to the actionable results of Forecastability Analysis. Here, products are segmented and grouped according to how well they forecast and their relative value to the business. The result is a set of specific policies that can be applied to these products that drive the forecast, inventory and capacity planning.

As an example, products where forecastability is high, the system should automate the forecast and mangers should monitor for exceptions. Or, products with low forecastability and low value should be forecasted at a family level or managed with inventory policies rather than spending time trying to forecast them directly.

So What?

So Forecastability Analysis is a novel approach to help you improve your forecast accuracy and process, but that is not the only result. As a part of Forecastability Analysis, you will develop a demand planning road map. With improved accuracy and policies in place, now you start to change your inventory and production execution strategy. As a result, inventory levels decrease and customer service increases. The business outcome for this improvement is of course increased revenue and/or improved margin.